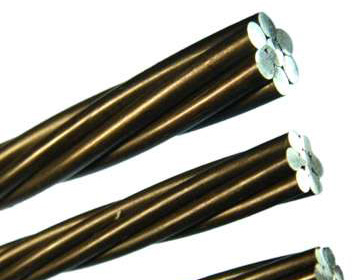

stranded galvanized steel wire

http://www.ahdqjt.com time: 10/19/10 09:41

stranded galvanized steel wire

|

name |

specification |

unit |

|

stranded galvanized steel wire |

1×7-5.4/1.8 |

ton |

|

stranded galvanized steel wire |

1×7-6.0/2.0 |

ton |

|

stranded galvanized steel wire |

1×7-6.0/2.0 |

ton |

|

stranded galvanized steel wire |

1×7-6.6/2.2 |

ton |

|

stranded galvanized steel wire |

1×7-7.8/2.6 |

ton |

|

stranded galvanized steel wire |

1×7-9.0/3.0 |

ton |

1. strand wire should have the same diameter, the same intensity, and the same level of zinc coating.

the diameter and the lay length should be uniform, and have no loose after cutting

strand wire should be tight; they should not be staggered, and have no breaking and bending.

2. strand wire and the overhead ground wire of 1 * 3 are not allowed to connected, other types of strand wire should be connected with welder. the distance between any two joints shall not be less than 50m; the measures should be taken to prevent the joints eroding.

3. mechanical properties

it should follow the 5.3 mechanical requirements in "people's republic of ferrous metallurgy industry standard yb/t5004-2001”.

4. coating quality

4.1 galvanized steel’s surface should be coated with uniform continuous layer of zinc, without cracks and open spots

4.2 zinc coating of the steel can have white spots, flash point and the individual accumulation of zinc layer, but can not affect the use. but the value of the local wire must not exceed 2 times as large as the positive deviation of the diameter.

4.3 the coating quality of the strand wire with the split shares should meet the following table:

coating quality

nominal steel diameter mm |

coating mass/(g/㎡) |

around the core posts |

||

|

special a |

a |

3 |

||

|

1.00 |

180 |

160 |

20 |

12 |

|

1.10 |

||||

|

1.20 |

||||

|

1.30 |

200 |

|||

|

1.40 |

30 |

|||

|

1.50 |

||||

|

1.60 |

180 |

|||

|

1.70 |

220 |

12 |

||

|

1.80 |

60 |

|||

|

2.00 |

230 |

200 |

14 |

|

|

2.20 |

80 |

|||

|

2.40 |

240 |

220 |

100 |

|

|

2.60 |

250 |

|||

|

2.80 |

270 |

250 |

130 |

|

|

3.00 |

270 |

|||

|

3.20 |

280 |

260 |

||

|

3.50 |

290 |

270 |

150 |

|

|

3.80 |

||||

|

4.00 |

|

|||

4.4 the zinc coating should be firmly enlaced 6 laps on the mandrel in the above table, no cracking or the zinc coating layer. it can not be able to wipe with the extent of bare fingers.

5. refer to "the people's republic of ferrous metals industry standard yb/t5004-2001 galvanized steel wire”.

"people's republic of ferrous metallurgy industry standard yb/t183-2000 strand of rare earth alloy coating”.

(b) the raw materials

1. the steel of the strand wire shall be used in the requirement of yb/t699-1999. the steel grades are 5 # or 50 #.

2. zinc ingot, used in galvanized steel wire, should use the zinc in gb/t470 of 0 or 1.

(c) factory inspection and testing methods

all the factory inspections are divided into full inspection and spot inspection. full inspection requires checking the appearance, structure, diameter, galvanized coating mass, twist method and its quality of each steel stranded wire.

1. inspect the surface quality of the strand by visual inspection.

2. use the measuring tool of 0.1mm to inspect the diameter of the strand.

3. breaking load test is required according to the standard gb/t8358-1987.

overhead conductors

尊龙登录 copyright © 2009-2011 anhui electric group shares co., ltd.